Please leave your feedback and contact information here so that we can further communicate with you.

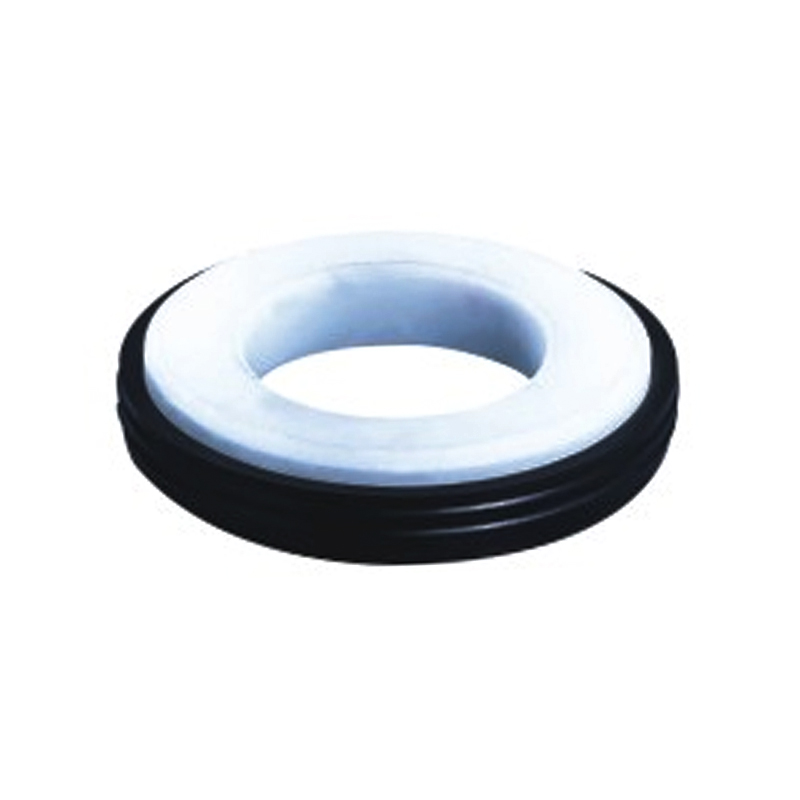

High Quality Centrifugal Pump Single Coil Mechanical Seal Assembly

In modern engineering, mechanical seals are critical components used to prevent leakage between rotating and stationary parts in machinery. Among the various types of mechanical seals, the Single Coil Mechanical Seal has gained significant attention due to its simplicity, effectiveness, and versatility. Over the years, this type of seal has undergone various developments, making it an essential part of various industries, from automotive to chemical processing.

A Single Coil Mechanical Seal is designed to provide a reliable sealing solution, especially in situations where high levels of efficiency and small maintenance are required. This seal consists of a single coil of metal, usually made from materials like stainless steel, which is used to maintain contact between the sealing surfaces. Unlike multi-coil designs, the single coil design reduces the complexity of the seal, making it easier to maintain and cost-effective to produce.

One of the primary benefits of the Single Coil Mechanical Seal is its simplicity. By utilizing a single coil, this mechanical seal eliminates the need for multiple components that could add to the cost, weight, and complexity of the sealing system. This streamlined design makes it easier to install and maintain, which is a significant advantage in industries where downtime can result in significant financial losses. Additionally, the single coil mechanism ensures a compact and lightweight seal, making it suitable for applications with limited space.

The evolution of the Single Coil Mechanical Seal has been closely linked to advancements in material science and manufacturing techniques. Early mechanical seals were often made from simple materials that lacked the durability needed for long-term performance. However, as materials such as high-performance alloys and ceramics became more widely available, the Single Coil Mechanical Seal was able to offer greater resistance to wear, corrosion, and temperature fluctuations. Today’s Single Coil Mechanical Seal can operate under more demanding conditions, ensuring extended service life even in harsh environments.

In addition to improved materials, advancements in sealing technologies have played a crucial role in the evolution of the Single Coil Mechanical Seal. Modern seals often incorporate advanced features such as spring-loaded mechanisms, which allow for self-adjustment and improved sealing performance. These features ensure that the seal maintains consistent pressure and contact between the sealing surfaces, which is critical for preventing leaks and ensuring the smooth operation of the machinery.

The widespread adoption of the Single Coil Mechanical Seal across different industries can be attributed to its versatility. Whether in pumps, compressors, or mixers, this type of seal can be used in a wide range of applications, making it indispensable in modern engineering. Its ability to handle various types of fluids and gases, combined with its resistance to wear and corrosion, makes it an ideal solution for industries such as water treatment, oil and gas, and chemical processing.

One of the significant benefits of the Single Coil Mechanical Seal is its ability to reduce leakage. In many applications, preventing leakage is crucial for maintaining operational efficiency and safety. The Single Coil Mechanical Seal offers an effective barrier against fluid leakage, which can reduce the risk of contamination, less product loss, and enhance safety in the workplace. This is particularly important in industries where the fluids being sealed are hazardous or expensive.

Another important advantage of the Single Coil Mechanical Seal is its cost-effectiveness. While there are other mechanical seals on the market, the simple design of the Single Coil Mechanical Seal makes it a more affordable option for many applications. This is especially beneficial for companies looking to reduce operational costs without compromising on performance. The lower cost of production and maintenance of the Single Coil Mechanical Seal makes it an attractive option for industries seeking efficient and affordable sealing solutions.

The use of the Single Coil Mechanical Seal has also contributed to environmental sustainability efforts. By reducing leakage and ensuring that machinery operates more efficiently, this type of seal helps less waste and the release of harmful substances into the environment. In industries such as chemical processing, where hazardous materials are often used, the ability to contain these substances effectively can reduce the environmental impact of operations.

Furthermore, the continued evolution of the Single Coil Mechanical Seal has made it a valuable component in the drive towards greater automation in engineering systems. With the development of advanced monitoring and control systems, the performance of Single Coil Mechanical Seals can now be continuously monitored, ensuring that they are functioning correctly and providing early detection of potential issues. This level of automation helps reduce the need for manual inspections and increases the reliability of equipment, contributing to overall operational efficiency.

As industries continue to evolve, so too will the Single Coil Mechanical Seal. The ongoing research into new materials, manufacturing techniques, and sealing technologies promises to further enhance the performance and reliability of this essential component. With its ability to meet the demands of modern engineering and its numerous benefits, the Single Coil Mechanical Seal will undoubtedly continue to play a vital role in the success of various industries for years to come.

In conclusion, the Single Coil Mechanical Seal has undergone significant evolution, making it a key component in modern engineering. Its simplicity, durability, and versatility have made it indispensable in a wide range of applications, from chemical processing to automotive industries. With continued advancements in materials and technologies, the Single Coil Mechanical Seal will remain an important part of sealing systems, offering improved efficiency, reduced leakage, and greater cost-effectiveness.

English

English русский

русский Español

Español